Automatic lubrication system

Automatic lubrication systems (ALS), also known as centralized lubrication systems (CLS), are mechanical devices designed to dispense precise quantities of lubricant to multiple points within machinery during operation. While typically fully automated, some systems may require manual activation via pumps or buttons and still fall under the centralized lubrication category.

ALS can be broadly categorized into two types:

- Oil systems, utilized for stationary equipment like CNC mills

- Grease systems, predominantly employed in mobile equipment such as trucks, mining, and construction machinery

These systems are essential for maintenance and reliability programs, providing lubrication points with metered amounts of grease or oil from a central reservoir. Reservoir sizes can range from 2 liters to bulk tanks, and the systems can be monitored remotely and linked to control systems.[1]

Purpose

Manual lubrication at optimal intervals is often impractical due to human resource constraints, available time, and the physical locations of lubrication points. Production cycles, machine availability, and workforce availability often dictate lubrication intervals, which may not be ideal for machine performance and longevity. Automatic lubrication systems ensure optimal lubrication during operation.

Benefits

Automatic lubrication systems offer advantages over manual lubrication:

- Comprehensive Lubrication: All critical components are lubricated, regardless of their location or ease of access.

- Operational Efficiency: Lubrication occurs while the machinery is in operation, ensuring even distribution within the bearings and increasing machine availability.

- Safety: Proper lubrication of critical components enhances the safe operation of machinery.

- Extended Component Life: Reduced wear from consistent lubrication extends component life, leading to fewer breakdowns, reduced downtime, and lower maintenance and replacement costs.

- Efficiency in Lubrication Use: Measured amounts of lubrication prevent waste.

- Worker Safety: Eliminates the need for workers to climb around machinery or access hazardous areas, improving overall safety.

- Energy Savings: Reduced friction results in lower energy consumption.

- Increased Productivity: Improved machine availability and reduced downtime enhance overall productivity.

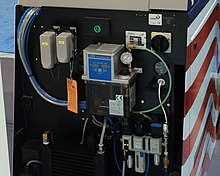

Components

The components of a typical automatic lubrication system consist of a controller/timer, pump with reservoir, supply line, metering valves, and feed lines. Regardless of the manufacturer or type of system, all automatic lubrication systems share these five main components:[2]

- Controller / Timer: This activates the system to distribute lubrication and can be linked to a POS system.

- Pump with Reservoir: This stores and provides the lubricant to the system.

- Supply Line: A line that connects the pump to the metering valves or injectors. The lubricant is pumped through this.

- Metering Valve / Injector: A component that measures and dispenses the lubricant to the application points.

- Feed Lines: Lines that connect the metering valves or injectors to the application points. The lubricant is pumped through this.

Types

Of the several types of automatic lubrication systems, they fall into two categories.

Pressure-relief type: also known as “piston lubrication system” or “positive displacement injector (PDI) system.” The piston distributor determines the output of lubrication points to ensure each lubrication point receives an accurate lubricant volume fed by the piston lubricator. This system is suitable for machines that require a precisely controlled amount of oil at each lubrication point.[3]

Resistance Oil Lubricators: The oil output of the lubrication point of the centralized oil lubrication system is subject to the resistance of an outlet with a continuous flow that directs lubricant without diversion to multiple outlets. It is recommended to use continuous flow distributors with proportion adapters or oil meter adapters to ensure the oil flow is more accurate at each lubrication point. This system is suitable for machines that do not require precise oil volumes for each lubrication point.[4]

Following are different types of systems to distribute the lubricant.

Single-line progressive

A single-line progressive system uses lubricant flow to cycle individual metering valves and valve assemblies. The valves dispense pistons moving back and forth in a specific bore. Each piston depends on discharge from the previous piston to shift and displace lubricant. If one piston does not shift, none of the following pistons will. The valve output is not adjustable.

Operation begins when the controller/timer sends a signal to the pump to start the lube event. The pump then feeds lubricant into the supply line, which connects to the primary metering valve, for either a preprogrammed amount of time or several times as monitored through a designated piston cycle switch. Lubricant is fed to the multiple lubrication points one after another via secondary progressive metering valves sized for each series of lubrication points and then directly to each issue via the feed lines.[5]

Single-line parallel

The first single-line parallel system for industry was introduced in 1937 by Lincoln Engineering (now known as Lincoln Industrial) in the United States.

A single-line parallel system can service a single machine, different zones on a single machine, or even several separate machines and is ideal when the volume of lubricant varies for each point. In this type of system, a central pump station automatically delivers lubricant through a single supply line to multiple branches of injectors. Each injector serves a single lubrication point, operates independently, and may be individually adjusted to deliver the desired amount of lubricant.[6]

Operation begins when the controller/timer sends a signal to the pump starting the lube cycle. The pump begins pumping lubricant to build up pressure in the supply line connecting the pump to the injectors. Once the required pressure is reached, the lube injectors dispense a predetermined amount of lubricant to the lubrication points via feed lines.[7]

Once the entire system reaches the required pressure, a pressure switch sends a signal to the controller indicating that grease has cycled through to all the distribution points. The pump shuts off. Pressure is vented out of the system and grease in the line is redirected back to the pump reservoir, until the normal system pressure level is restored.[7]

Dual-line parallel

A dual-line parallel system is similar to a single-line parallel system in that it uses hydraulic pressure to cycle adjustable valves to dispense measured shots of lubricant. It has 2 main supply lines which are alternatively used as pressure/vent lines. The advantage of a two-line system is that it can handle hundreds of lubrication points from a single pump station over several thousand feet using significantly smaller tubing or pipe.

Operation begins when the controller/timer sends a signal to the pump to start the lubrication cycle. The pump begins pumping lubricant to build up pressure in the first (the pressure) supply line while simultaneously venting the second (vent) return line. Once the required pressure is reached, a predetermined amount of lubricant is dispensed by the metering devices to half of the lubrication points via feed lines.

Once the pressure switch monitoring main supply line pressure indicates a preset pressure in the line has been reached, the system is hydraulically closed. The controller shuts off the pump and signals a changeover valve to redirect lubricant to the second main supply line.[8]

The next time the controller activates the system, the second main line now becomes the pressure line, while the first line becomes the vent line. The second line is pressurized and the entire process is repeated, lubricating the remaining lube points.[8]

Multipoint direct lubricator

When the controller in the pump or external controller activates the drive motor, a set of cams turns and activates individual injectors or pump elements to dispense a fixed amount of lubricant to each lubrication point. Systems are easy to design, direct pump to lube point without added accessories, and easy to troubleshoot.

See also

- Tribology